Below is the (ongoing) resultant data

including pictures of the setup and description of the implementation.

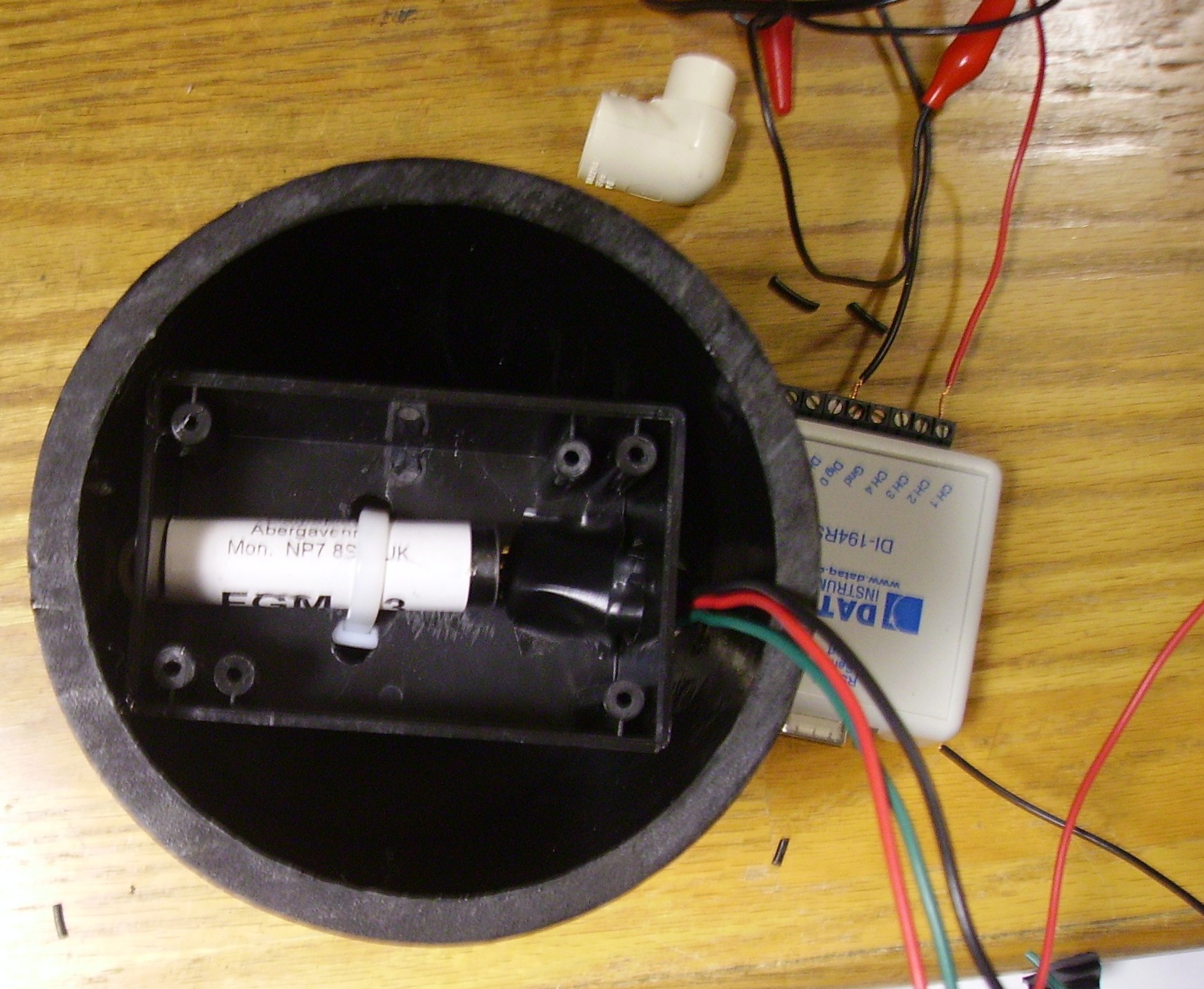

The

design uses an SCL field sensor type FGM-3 (From Fat Quarters

Software). The signal from this unit is fed into the integrated circuit

which performs all the functions required to the level of providing a

digital output on eight parallel lines which mirrors the tiny field

fluctuations. This output is then fed directly to the input

port of a serial-to-ether server which forwards the data over wired

(CAT-5) Ethernet to a computer for data analysis.

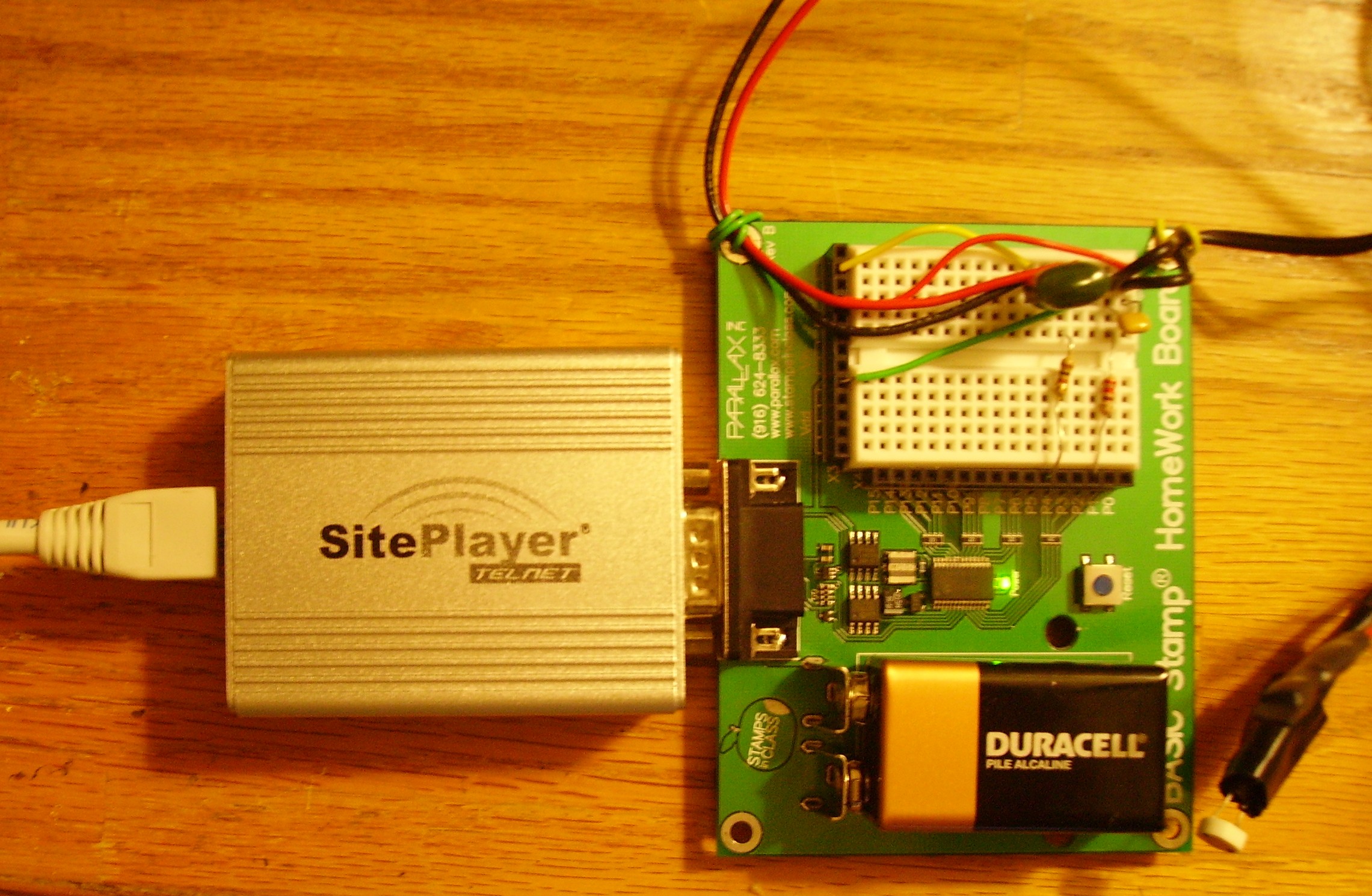

To remotely deploy this sensor,

I am using the SITE Player Telnet Serial-to-Ether

converter/controller from Netmedia.com

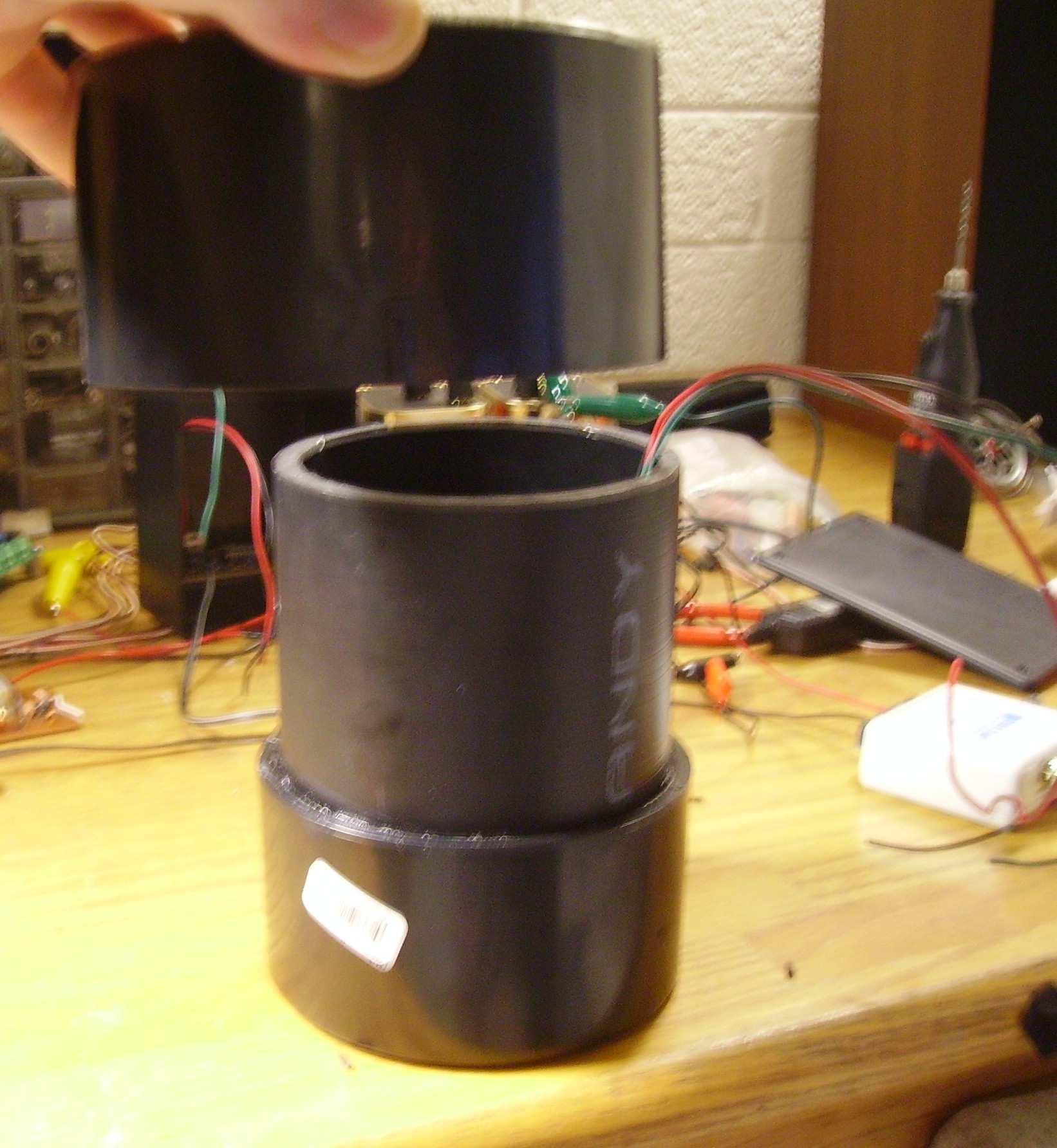

The Sensor (FGM-3) is housed inside a small

section of 4" PVC tube that is capped on both ends with PVC

ends.

Here is the container with the PVC Cap About

to be placed onto it.. note the wires exfiltrate the container thru a

small hole drilled in the top of the upper PVC Cap.... the wires are

sealed on both sides with a rubber grommet and silicon sealant to

ensure the inside of the container remains Waterproof.

In the future, I hope to employ the Zigbee

type "Xbee" wireless network transceiver set so I can get rid of the

Cat-5 cable (if the price of the zigbee technology comes down abit).

Here is a picture of the Temperature/Light

Sensor Suite and it's connection to the SitePlayer which converts the

Serial output from the Basic Stamp to ethernet for the run over CAT5

cable into our Lab. A second SitePlayer Converts the Data back into

serial as it is fed into the logging computer's Serial port.

The use of SitePlayer enables the use of (available) long data runs

using them as serial to ethernet bridges. Notice the Temperatureand

light sensors are extended 20" on wires from the basic

stamp and the basic stamp's power supply is provided by a 9V adapter

piggy backed off the site-player's power supply (not a 9v battery) near

the sensor array.

Temperature and

Light Readings are taken at the same time as the magnetic readings

enabling analysis of the magnetic data to be correlated with

the Temperature

and light intensity readings.

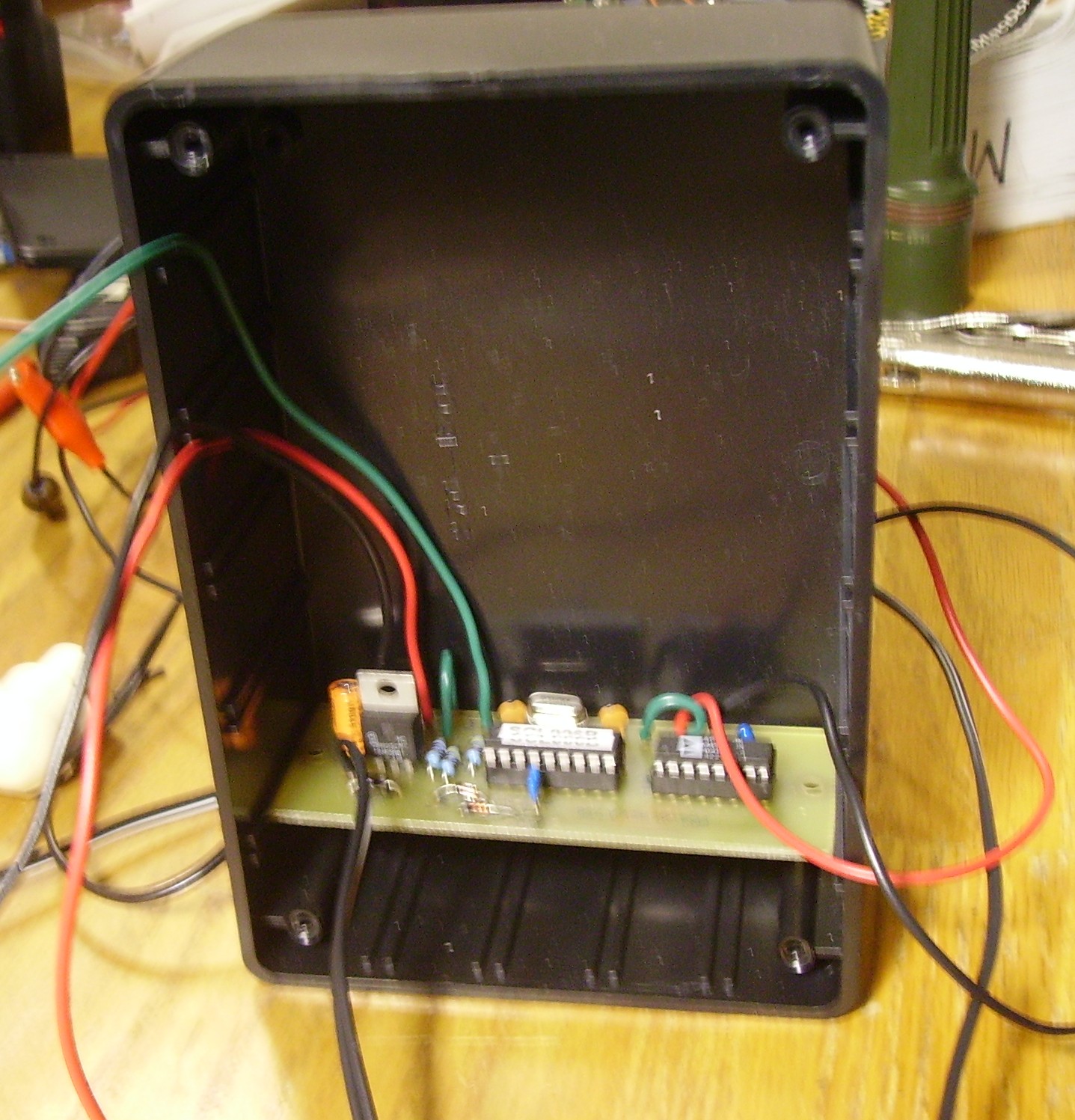

The PC Board (Below) is connected to the

FGM-3 Sensor and enables users to specify 1 of 4 sensativity levels

(switch) as well as a sensor reset button which I've noticed comes in

quite handy. The Board is mounted into a standard Plastic Enclosure

that is near a "Wall Wart" Double Regulated Powersupply.

The Sensor's Rectangular Signal is

fed into the PC Board which performs all the

functions required to the level of providing a digital output on eight

parallel lines which mirrors the tiny field fluctuations.

This output can be fed directly to the input

port of a computer... the PCB's IC converts the period

variations to an eight bit digital

output, (after amplification and comparison to a

chosen zero reference).

The sensors will be buried

underground 14" below the surface of my back yard to help stabilize the

units Temperature as

variances in the FGM-3 Sensor's operational Temperature

will cause the readings to change. Therefore a Temperature/Light:Magnetic

Flux reading correlation must be implemented.

Much More Pictures/data to come!